Textile industry case application

Importance of air compressor in textile industry

The textile industry has always been closely related to our daily lives. Compressed air, as the second largest power source after electricity, is an important power source for the textile industry and is widely used in the production of modern textile enterprises.

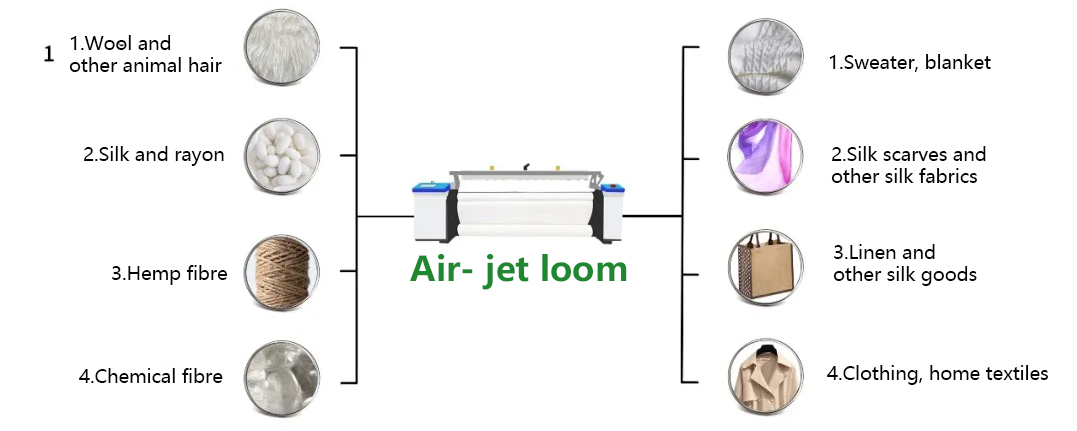

The main air-consuming equipment in the general textile and chemical fiber industry includes air-jet looms, air-coated yarn machines, Elasticizer machines, fiber material conveyors, etc. Among them, air-jet looms are the equipment with the largest air consumption in the textile industry. Its working principle is to use air as the weft insertion medium, and use the ejected compressed air flow to generate friction traction on the weft yarn to pull the weft yarn through the shuttle, and achieve the purpose of weft insertion through the jet generated by the jet.

Project Background

XX Textile Enterprise in Shandong Province is a high-end textile enterprise specializing in the design and production of various high-end textiles, infant clothing, and textile machinery accessories. Its business has spread all over the country.

There are currently 30 air jet looms running simultaneously in the customer's factory, with a large demand for gas. The original factory used a 110kw 5bar screw air compressor. Due to the expansion of the factory, the gas demand increased. A 37KW TA-37A/3EPM screw air compressor was added to run simultaneously. However, the original equipment pressure was high, and the air supply for the air jet loom that only required 3bar pressure was very unstable. In order to further ensure the air supply, the customer To maintain stable air pressure and reduce unnecessary energy consumption, it is necessary to transform energy-saving and consumption-reducing equipment. The specific transformation plan is as follows:

The Tecbell team communicated with customers for many rounds, visited on-site, tested the air consumption and pressure of air jet loom equipment, and customized professional, energy-saving and reliable technical solutions for customers in line with customer production needs and process characteristics. Tecbell uses 132KW TA-132A/3EPM permanent magnet variable frequency screw compressor to replace the original 110kw pressure 5bar screw air compressor, plus supporting post-processing equipment. Through layers of protection, it not only ensures the cleanliness of production gas, but also makes compressed gas more stable, more energy-saving and higher quality.

Tecbell team conducts on-site inspection

Tecbell team conducts on-site inspection

At present, Tecbell's permanent magnet variable frequency air compressor has been running smoothly for several months. Compared with the old machine, the current air equipment consumes less materials, has high efficiency, stable air supply, stable machine operation, and a comprehensive energy saving rate of 15%. The finished fabrics are now lighter than before, with perfect patterns and better quality. The overall quality of customer products has been improved, and the operating results have been recognized and praised by customers.

Air jet loom operating status

Tecbell adheres to the concept of "ingenious quality, supreme service" to provide more reliable, more energy-saving products and high-quality compressed air for all walks of life.

The main advantages of using Tecbell permanent magnet variable frequency screw air compressor

The textile industry is a typical gas consumer with large gas consumption, long operation time and high power consumption. Insufficient gas production will affect the normal production and operation of the enterprise. Tecbell permanent magnet variable frequency screw air compressor has more stable gas supply pressure, higher efficiency and longer service life

⏩Constant exhaust pressure, stable pressure fluctuation within ±0.01MPa, effectively improving gas source quality, reducing gas consumption, optimizing energy efficiency, and reducing energy consumption by 30%~50%

⏩Full range of Huichuan high-performance heavy-duty inverters, more stable operation

⏩Exceeding Class 1 energy efficiency standards, permanent magnet variable frequency synchronous motor efficiency up to 97.4%

⏩IP55 permanent magnet variable frequency synchronous motor, SKF new bearing structure, longer service life