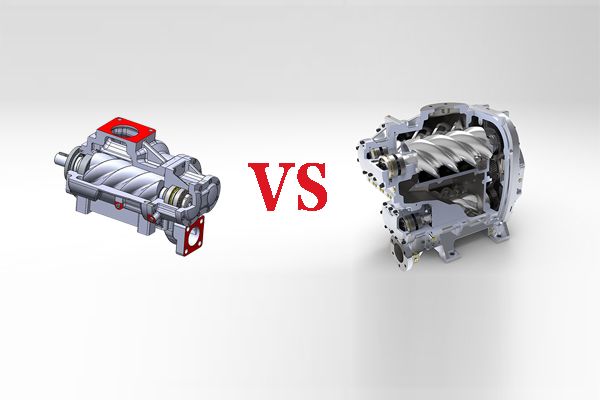

Single-screw and double-screw air compressors have always been a more confusing problem for users to select; So what is the difference between a single screw and a double screw? The following points are summarized:

1. Applicability

Single-stage compression screw air compressor : suitable for high-pressure air compressors, refrigeration compressors, natural gas compressors and other high exhaust pressure occasions.

Double-stage compression screw air compressor : Due to the limitations of rotor stiffness and bearing load, double-stage compression screw air compressor can only be used in the middle and low pressure range, such as power air compressors, refrigeration compressors and low pressure natural gas compressors above 4.5MPa.

2. Processing equipment

Single-stage compression screw air compressor : lack of mature special processing equipment, resulting in unstable product performance.

Double-stage compression screw air compressor : We have a mature screw milling machine to ensure stable product performance.

3. Reliability

Single-stage compression screw air compressor : The star wheel of the single-stage compression screw air compressor is a wearing part. In addition to the high material requirements of the star wheel, the star wheel should be replaced regularly.

Double-stage compression screw air compressor : The double-stage compression screw air compressor has no wearing parts and can operate for 40,000 to 80,000 hours without trouble.

4. Efficiency

Single-stage compression screw air compressor : medium speed (1500~3500r/min), high efficiency, direct connection, specific power 5.9~6.4KW/(m/min)

Double-stage compression screw air compressor : high speed (3000-7000r/min) high efficiency, with acceleration device, specific power 6.0-6.6KW/(m/min) the same. Over time, the star wheels of single-stage compression screw air compressors wear out, reducing gas output and efficiency.

5. Noise and vibration

Single-stage compression screw air compressor : low vibration, low noise, typical value 60 ~ 68 dB(A).

Double-stage compression screw air compressor : high-frequency noise when two metal screws mesh, 64~78 dB(A).

The above is the difference between single-stage compression air compressor and double-stage compression screw air compressor. If you do not know how to select and match, you can contact us. We will serve you wholeheartedly.